The E611i Helps Detect Surface Defects and Anomalies in the Manufacturing process

Background

In industrial production, a component needs to go through multiple processing steps to form, such as: machining, polishing, coating with different materials, etc. In order to ensure the quality of the final product, each processing procedure requires a strict quality inspection and feedback system. In the traditional manufacturing lines, inspection of human eyes was the main way. However, with the development of manufacturing and industrial automation, the market requires more and more sophisticated parts, and the processing procedures are becoming more and more complicated. As for large-volume products, relying solely on traditional inspection way can no longer meet the demand, which not only consumes time and effort, increases costs, but also cannot guarantee the accuracy of detection results. Therefore, artificial intelligence-based visual inspection technology is becoming more and more popular in industrial automation, and has been widely used in manufacturing processes to help manufacturers reduce production costs while greatly improving production efficiency.

Demands of Customer

A customer of Future Robot is engaged in the manufacture of precision components. After each processing process is completed, the parts need to be inspected for defects and abnormalities. Due to the small and precise parts and the complex environment in the production scene, it is very difficult for machine vision to detect defects, so good image processing equipment now is required. The following are the specific requirements of customers for equipment:

1. Non-touch real-time detection, fast image processing speed;

2. Flexible, efficient and high-precision detection;

3. The detection process is stable and not easily disturbed by the surrounding environment;

4. Connect a variety of devices with different functions.

Products Recommended

According to the customer's needs, Future Robot recommended the E611i Embedded Industrial Computer as the core hardware equipment of the detection system. The product features are as follows:

1. Based on Intel's 10th generation Comet Lake processing platform;

2. 2 DDR4 SO-DIMM slots support up to 32GB memory;

3. 3 Ethernet ports, each network port is controlled by an independent Intel chip (2 Intel I211-AT, 1 Intel I219-LM);

4. 6 serial ports (3 RS-232, 3 RS-232/485);

5. 8 USB ports (4 USB 3.0, 4 USB 2.0);

6. 2 DP and 1 VGA, support dual independent display;

7. Adopt rugged and compact design

Field Application

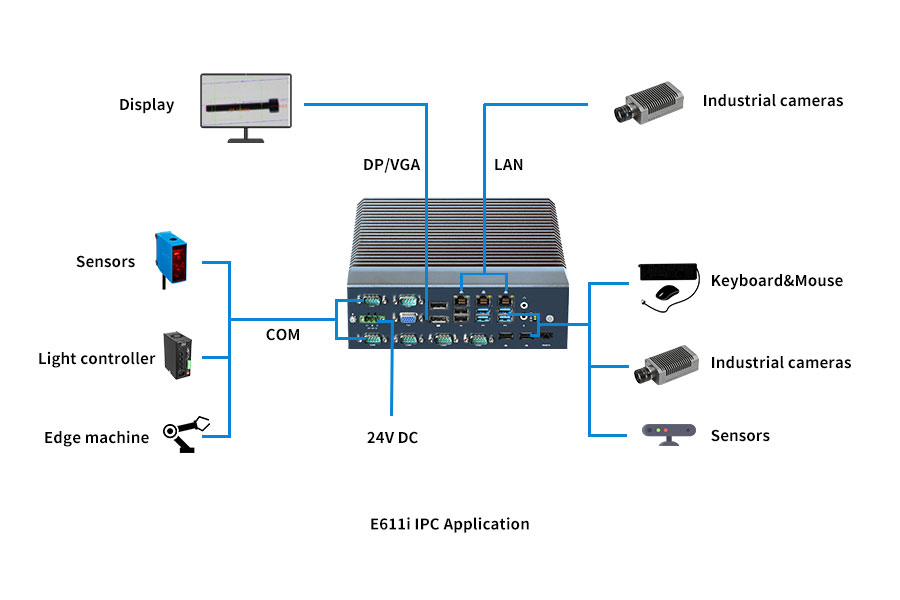

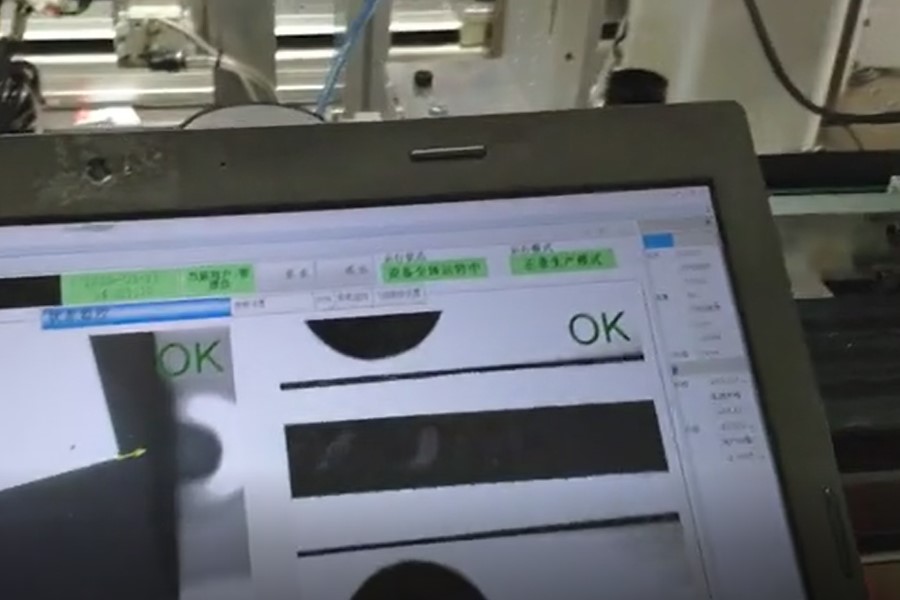

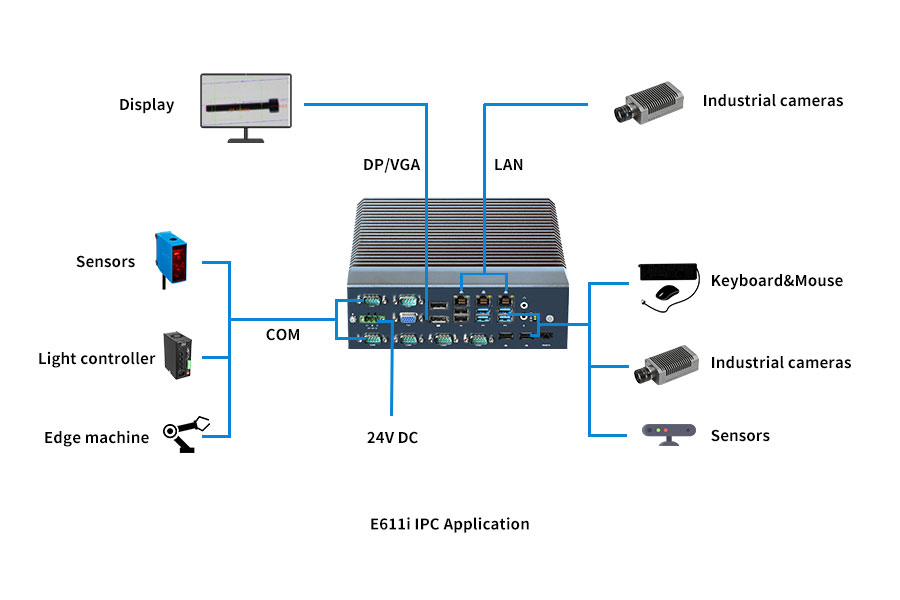

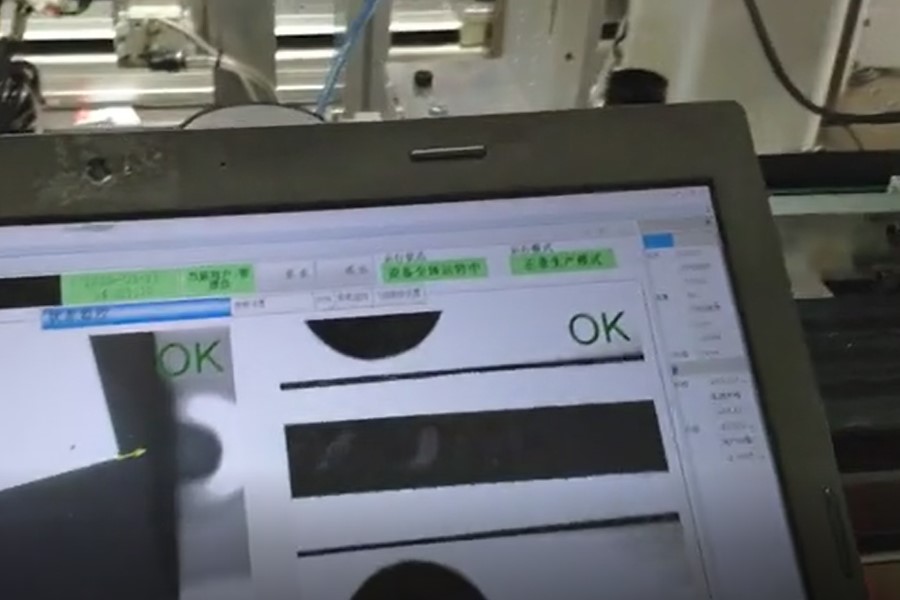

The industrial camera is connected to the E611i Embedded Industrial Computer through the LAN port or the USB port. The acquisition device collects the image in real time and then transmits it to the E611i at high speed. Based on the powerful computing capability of the E611i, it calculates the characteristics, and then the industrial computer controls the edge mechanical equipment to perform actions such as classification and elimination according to the analysis results.

The product interface application is as follows:

Application advantages:

1. Powerful data transmission and processing capabilities: Based on the tenth generation Intel CPU, E611i has good data processing capabilities, and can analyze and process images collected by the acquisition equipment in real time;

2. Stable operation: Adopting a reinforced structure design, even in harsh industrial environments, it can still operate stably without external interference;

3. Rich interfaces: E611i has various interfaces such as network port, serial port, USB, DP and VGA, which can meet the needs of the detection site to connect various devices such as sensors and displays, and realize function expansion.

4. Compact and easy to install: E611i is small and compact, saving space, and the installation process is simple, and the utilization rate of time and space is further improved.

In the application of surface quality inspection, the E611i series industrial computer improves the efficiency of production line quality inspection, and at the same time ensures the accuracy of inspection, saves production costs for enterprises, and reduces defective products flowing to the market.

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us