Machine vision (MV) is an inspection machine equipped with sensing vision instruments (such as auto-focus cameras or sensors), in which optical inspection instruments account for a very high proportion and can be used to detect defects in various products , or use it to judge and select objects, and apply it to the calibration and positioning of materials on the automated production line. It is the most industrialized part of computer vision, and it is mainly used in factory automation inspection and robot industry.

Nearly 80% of industrial vision systems are mainly used for inspection, including improving production efficiency, controlling product quality in the production process, and collecting product data. The classification and selection of products are also integrated in the detection function.

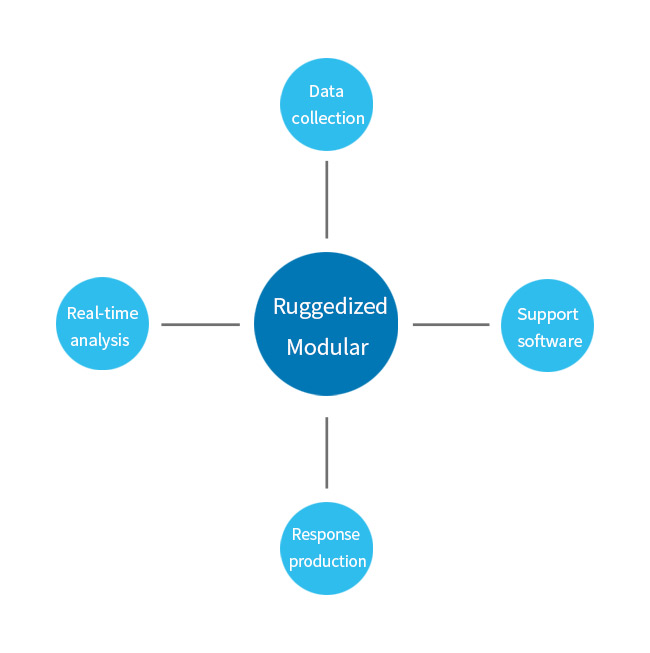

The vision system detects the products on the production line, determines whether the products meet the quality requirements, and according to the results, generates corresponding signals to be input to the host computer. Image acquisition devices include light sources, cameras, etc.; image processing devices include corresponding software and hardware systems; output devices are related systems connected to the manufacturing process, including programmable controllers and alarm devices.

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us