All-in-one solution with integrated PC-Based Motion Control, Vision Cell, and Logic Control

All-in-one solution with integrated PC-Based Motion Control, Vision Cell, and Logic Control

Highly integrated, cost-saving and efficient solution

Source: Future Robot Technology Co., Limited

Paper in PDF

With the rapid development of electronic product technology worldwide, electric consumers have increasingly higher requirements on the appearance, performance and quality of products, so the major electronic product manufacturers have become more and more strict with their own product processing technology. Taking electronic products as an example, the traditional camera and mirror assembly process also needs to be changed. The traditional simple assembly, adding glue and sealing rings, constitutes a camera with waterproof and dustproof performance, towards high integration, the development of high precision and high reliability has become the new direction of our packaging process research. The traditional assembly process cannot meet the requirements of integration, high precision and high reliability, so it is necessary to add equipment for assembly dispensing, fast curing, and labor saving.

Industry Status

The production volume of various electronic products is huge with the popularity of electronic appliances and rising demand. In order to ensure the complete functionality of the product, it is also indispensable for automated production and inspection. At present, most production companies still use manual testing. For daily production volume, manual inspection has high cost, low efficiency, and low cost performance. Based on the current market demand and development, from the perspective of cost-effective, speed, and reliability, automated production and machine vision inspection system puts forward higher requirements.

For automated production and visual inspection equipment vendors or system integrators, the systems used in traditional solutions are very complex, and quickly building differentiated solutions is a major challenge. As a benchmark, it requires:

Industrial computer - communication, control and vision processing

Frame grabber - Digitally captured images

Light source controller - connect to lighting equipment

PLC / motion controller - motion control

Pain points and customer demands

Then the integrated solution of integrated visualization, vision, motion and logic control has become the demand of equipment manufacturers and integrators, reducing the overall cost of the solution, reducing on-site labor costs and maintenance costs. Integrate new enterprise IoT functions and use artificial intelligence (AI) to make it more efficient.

Factory automation requires that the entire control system is highly integrated to ensure the coordination of the entire production system. A large number of analog, digital, pulse, and switching signals are collected and processed through specially designed multi-channel input and output and high-speed processing by industrial computers is used for process control, motion control of an actuator, and multiple components on site Batch control and logic control. Based on high-speed processors, massive memory, multi-threaded processing, and high-speed communications, it better integrates all related systems, and has better coordination capabilities and faster processing speeds.

Solution

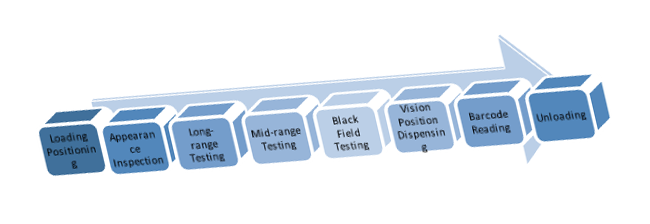

Taking the mobile phone camera module automatic/semi-automatic detection workstation as an example, the entire workstation involves 4 motion and visual operating environments: loading position, appearance inspection, visual position allocation and barcode reading, and integrates 6 industrial cameras, as shown in Figure 1:

Figure 1. Cellphone camera module auto/semi-auto inspection workstation

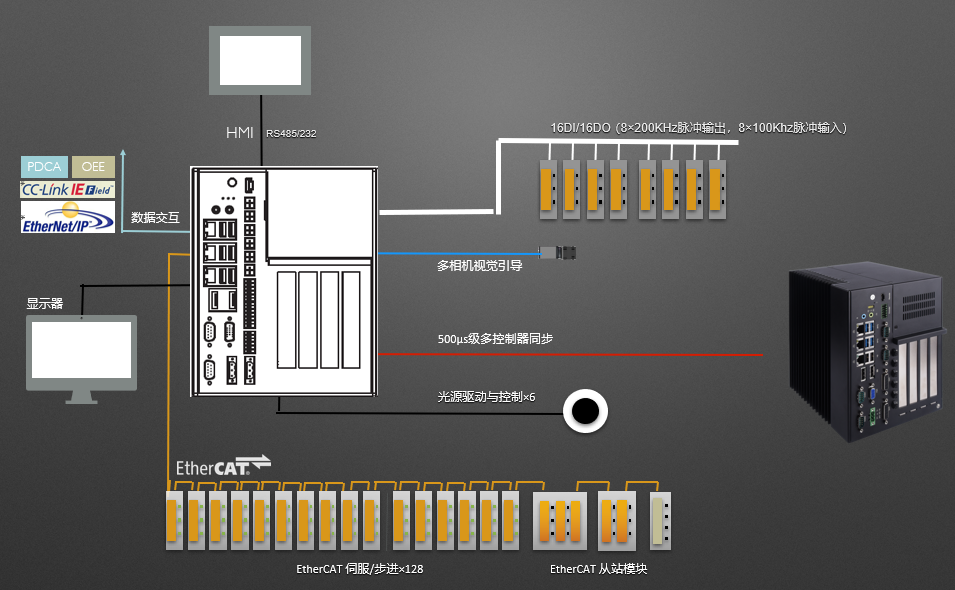

The operation of the workstation requires powerful CPU computing ability combined with real-time and virtualization tools to achieve EtherCAT industrial bus motion control; the production environment is dust-free and requires Fanless design. Future Robot Technology Co., Ltd launched the following solutions:

Visual motion controller, integrated motion control, visualization, vision cell, logic control

Various standardized development languages: Japanese ladder diagram, C/C++, structured text, function block

Based on windows + real-time system, open and higher execution efficiency

Analyze machine process data and build learning models to optimize key equipment data

Customer Benefit

Highly integrated, cost-saving and efficient solution

The solution facilitates more rapid and effective data processing and mutual communication, can flexibly control each terminal in the industrial control environment and can quickly communicate with each other, and also enables the control system to be closely integrated with the upper management system for easy production monitoring and management.

The overall solution has low cost of ownership, strong data processing capabilities, easy installation and use of systems and software, short application development cycles, good human-computer interaction, convenient network communication, advanced diagnostic functions, better software transparency, and low system maintenance costs Wait.

Solution Features

V500 series Expandable Fanless Embedded Industrial Computer is based on Intel KABY lake-S platform, using Intel real-time and virtualization tools to achieve EtherCAT industrial bus motion control.

Intel® 6/7th Generation Desktop Processor

2x DP and 1x VGA interface, support 2 independent displays

2x DDR4 SO-DIMM memory slots, up to 32GB

1x PCIe Gen3 x16, 1x PCIe Gen2 x2, 2x PCI slot

3x Intel Gigabit Ethernet interface (2 Intel i211-AT and 1 Intel i219-LM)

6-channel light source control, 2x Encoder, 32-channel high-speed isolated industrial digital I/O

Rugged Fanless structure design

V500 series of Embedded Industrial Computer can also be called PC-Based motion controllers. This industrial computer has high integration, powerful performance, good reliability, high accuracy and compatibility with local cloud platforms. It is ideal as an embedded solution.

The extensive digital I/O support and interface flexibility provided by FPGA allows system integrators to quickly define unique implementations for specific use cases.

Support various open APIs, which can be integrated with Google Cloud, Alibaba Cloud, and various other platforms and services.

This is an open system. Based on the existing technical achievements and related knowledge, engineers can design the entire control system faster and better. The human-machine interface is friendly, the interface is very simple, and the versatility of the components is good, so the debugging and maintenance of the entire system is also very simple. The access to information in the system is very convenient, and the communication with other upper layers is also very simple, and the relevant information can be seen at a glance.

It has a good HMI. During the control process, various related information is displayed one by one, making it easy for the operator to operate the entire system. One can also perform real-time programming to achieve functions that cannot be completed by other systems and achieve the overall control.

Future Robot Technology Co., Limited (Future Robot in short) is a high-tech innovation enterprise focusing on Intelligent Manufacturing and Artificial Intelligence. Future Robot, with strong R&D capability and market demand-orientation, design and provide worldwide enterprises and individual users with Industrial Smart Camera, Vision Controller, Fanless Embedded Computer, Frame Grabber, USB3.1 Expansion Cards products which are for Industrial Automation, Robot, Machine Vision, Medical Application, Intelligent Transportation, Education and Internet of Things applications.

Expert team with rich experiences in Machine Vision, Motion Control and Edge Computing:

Hardware engineering team

- x86, FPGA, DSP, Layout and testing Engineers

Software engineering team

- BIOS engineers, FPGA, DSP, Algorithm software engineers and system development engineers.

Industrial and structure design engineering team

- structure design, multi board and model design

As a member of Intel IoT Solutions Alliance and partner of Intel IoT RFP Ready Kits, Future Robot Technology Co., Limited aim to provide reliable, high efficient and cost-effective standard and customized solutions for the customers worldwide.

Intel ISA (IoT Solutions Alliance, Industrial Solution Builders Specialist) member link: https://www.intel.com/content/www/us/en/internet-of-things/ai-in-production/partners/shenzhen-futurerobot-technology.html?wapkw=futurerobot%20technology

Linkedin paper link: https://www.linkedin.com/pulse/all-in-one-solution-integrated-pc-based-motion-vision-lynn-xu

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us